|

PO Box 190

Milltown, NJ 08850 1-732-928-5311 PH 1-732-928-5332 FX |

Hot Rubberized Crack Sealing:

Joints or cracks in pavement, if not sealed properly, will allow water, dirt and other foreign materials to enter. As water soaks down through the unsealed cracks, increasing damage will occur through the freezing and thawing cycles. Allowing water to penetrate beneath the joint or crack will also displace the subgrade, which will cause further cracking and generally deteriorate the traffic surface.The program of sealing cracks and joints with hot poured rubberized sealing compund has been ongoing for many years, resulting in substantial savings in maintenance costs.

USES:

Hot-Pour rubberized crack or joint sealing materials are used on highways, public streets, private roadways and parking lots (residential, commercial and industrial), track and bus terminals, traffic loops and airport runways. Without an ongoing sealing program, the otherwise durable pavement surface will have its life expectancy dramatically shortened. LONG TERM SAVINGS:

Joints or cracks sealed with hot-pour, rubberized material have been proven to out perform cold applied and non-rubberized compounds. Although the initial application of hot-pour materials may cost slightly more, this cost is returned in the added years of pavement life. The growing demand for these products through-out North America and other parts of the world comfirms large savings in maintenance. |

|

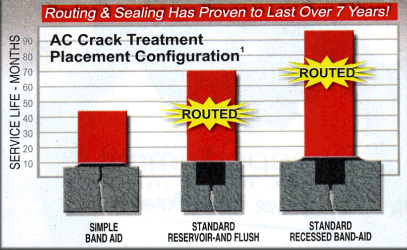

APPLICATION PROCEDURES:

Step 1: Routing The use of routers in cracks or joints ensures cleanliness and superior vertical sidewalls. This allows for a greater bonding surface. Step 2: Crack or Joint Cleaning After the routing operation is completed, all cracks or joints should be clean, dry and free from any foreign debris. This is achived with portable air packs with a wind velocity of 340km/hr. Step 2(a): Optional cleaning method on asphalt surfaces. This method uses hot compress air lance, which will both clean and dry the cracks or joints. The heat of the lance will also improve the bond of the hotpoured, rubberized crack sealing material. Step 3: Material Application. The hot-poured, rubberized material will conform with the latest N.J. DOT specifications. The material will be flush with the adjacent pavement or be feathered to prevent damage by snow ploughs. All material will be applied using material manufacturers specifically designed methods. Step 4: Traffic Flow Hot rubberized material formulated for parking areas will not track or stick to shoes. There is no need to disrupt traffic flow. |